- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

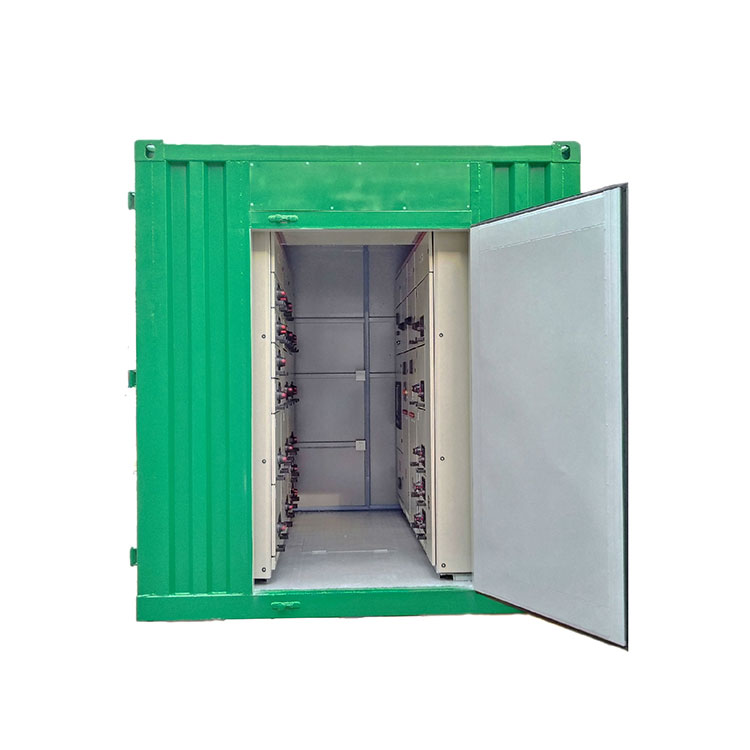

33kv 11kv Medium Voltage Padmount Substation

Send Inquiry

Video

33kv 11kv medium voltage padmount substation Operation Requirements:

1. Operational Inspection

A comprehensive inspection must be carried out before the operation of the box-type substation to ensure that all tasks are adequately prepared and to initiate the initial operation. During routine operation, regular inspections and maintenance are necessary to address any issues promptly.

2. Temperature and Humidity Control

Temperature and humidity control is crucial during the operation of the box-type substation. The internal temperature of the box-type substation should generally be maintained between -5°C to +40°C, with humidity levels below 85% relative humidity. To ensure stable temperature and humidity, ventilation equipment, heating devices, and air conditioning equipment are typically installed within the box-type substation.

3. Voltage Control

The box-type substation must maintain a stable voltage during operation to ensure the quality of power and a steady power output. To achieve this, the box-type substation is usually equipped with voltage control devices capable of automatically or manually regulating the output voltage.

4. Protection Device Control

The box-type substation must be equipped with a comprehensive protection system to ensure the safety and stable operation of the equipment. To guarantee the reliability and safety of these protection devices, regular inspections and maintenance are necessary, in addition to following relevant electrical safety regulations and operating procedures.

5. Routine Maintenance

Routine maintenance is crucial for ensuring the stable operation of the box-type substation. It includes moisture-proofing, corrosion prevention, cleaning, fastening, and more. Additionally, regular equipment inspections and prompt issue resolution are required to ensure the safety and stability of the equipment.

CONSO·CN 33kv 11kv medium voltage padmount substation Detail:

Container Shell

|

Steel Shell

|

Laminate Shell

|

CONSO·CN 33kv 11kv medium voltage padmount substation Workshop:

|

Compact Shell in Process |

Switchgear is Testing |

Daily Clean Up |

Workshop Overview |

33kv 11kv medium voltage padmount substation in Assembling:

|

KYN28 in Process |

HXGN12 in Process |

GCS in Process |

GIS in process |

Switchgear Assembled with the Shell

33kv 11kv medium voltage padmount substation in Package:

33kv 11kv medium voltage padmount substation Ready to ship: