- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

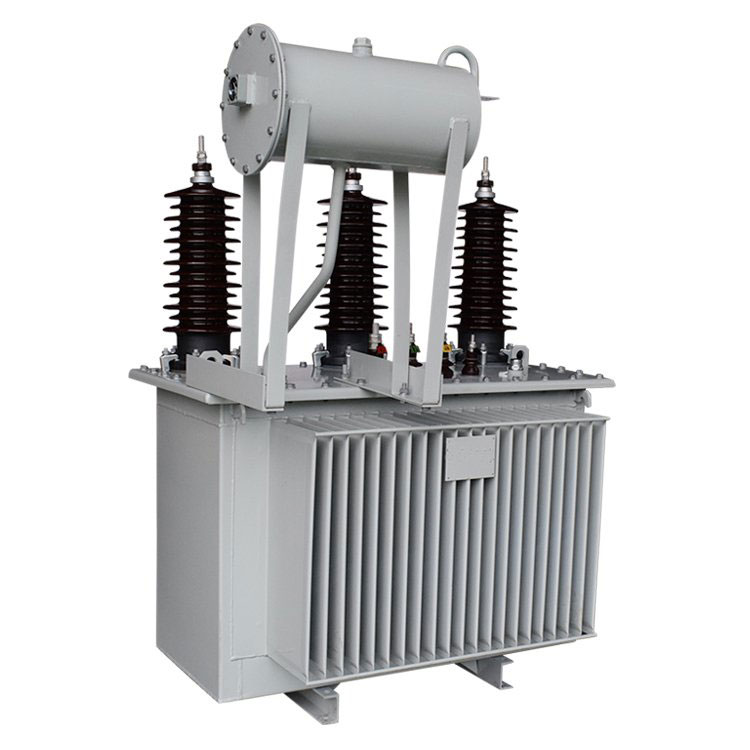

33kv 250 Kva Copper Three Phase Distribution Transformer

Send Inquiry

Video

The 33kV 250 kVA copper three phase distribution transformer Induction:

The 33kV 250 kVA copper three phase distribution transformer is a stationary electrical device used to transform one set of alternating current voltage (or current) values into another set with the same frequency but different voltage (or current) values. When an alternating current is applied to the primary winding, it generates alternating magnetic flux. This alternating magnetic flux, through the magnetic permeability of the iron core, induces an alternating electromotive force in the secondary winding. The magnitude of the secondary induced electromotive force depends on the number of turns in the primary and secondary windings, meaning that the voltage is directly proportional to the number of turns.

Its primary function is to transmit electrical energy, and therefore, its rated capacity is a key parameter. The rated capacity is a standard value representing the power, indicating the magnitude of electrical energy transmission, and it is expressed in kVA or MVA. When the transformer is subjected to its rated voltage, the rated current is determined based on it to ensure that the temperature rise remains below specified limits under the prescribed conditions.

The 33kV 250kVA copper three phase distribution transformer Technical Data:

| Mode: | S11-M-250 or depends; |

| Rated Capacity: | 250 kVA; |

| Power Frequency withstand Voltage: | AC 85kV; |

| Lighting Impulse withstand Voltage: | AC 200kV; |

| No Loading Loss: | 395± 10%W; |

| Loading Loss: | 3685± 10%W; |

| Cooling system: | ONAN for Oil filed, AN/AF for dry type; |

| Insulation Material: | 25# 45# Mineral Oil or epoxy resin; |

| Vector Group: | Yyn0; |

| Tapping Method: | 2.5% for one step overall step 5 steps , offline tapping; |

CONSO·CN The 33kV 250kVA copper three phase distribution transformer Detail:

Oil Filled

|

Oil Emptied

|

Amorphous Alloy

|

Rolled Iron Core

|

CONSO·CN 33kV 250kVA copper three phase distribution transformers Workshop:

|

Winding Workshop |

Coil Drying Area |

Oil Filling Area |

Finished Product Area |

The 33kV 250kVA copper three phase distribution transformer Testing Center:

The 33kV 250kVA copper three phase distribution transformer Producing Equipment:

|

Transformer Oven |

Casting Equipment |

Foil winding machine |

CONSO·CN The 33kV 250kVA copper three phase distribution transformer Ready to Ship:

Package method:

|

Wooden Box |

Steel Structure |