- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

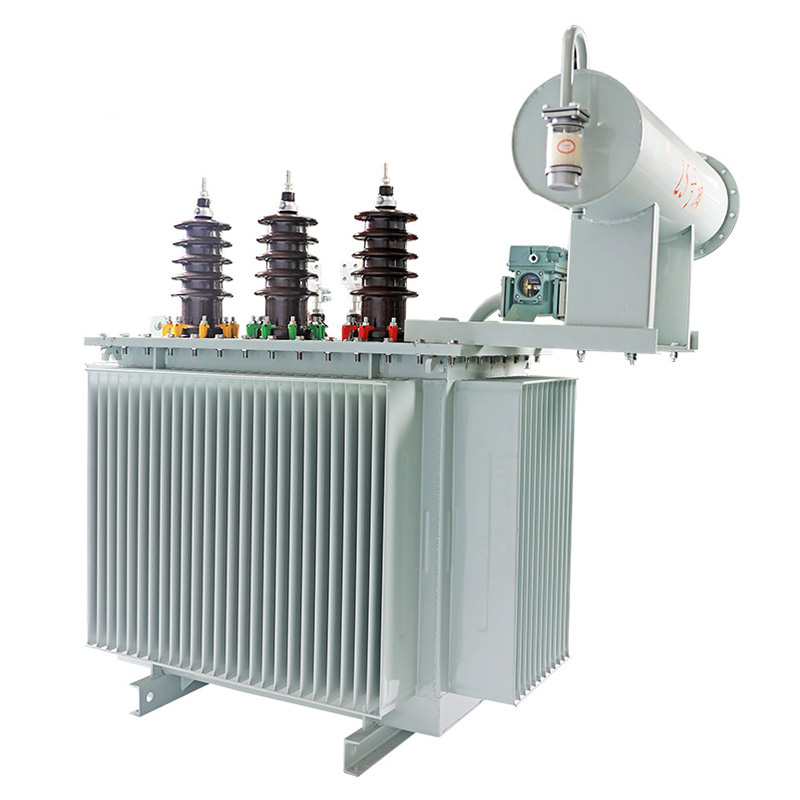

35 Kv 20000 Kva Power Transformer

Send Inquiry

Strategies to Improve the Economic Operation of Power Transformers:

Having gained an understanding of the structure and working principles of power transformers and analyzed the factors that affect their economic operation, the next step is for relevant personnel to enhance the economic efficiency of power transformer operation through effective improvement measures. The following analysis focuses on several key aspects:

1 Utilizing Advanced Technological Methods

When aiming to improve the economic operational efficiency of power transformers, power companies should place a strong emphasis on adopting advanced electrical technology and methods. By implementing advanced improvement techniques, companies can enhance their economic development. Additionally, enterprises should improve traditional methods in the power system, with a particular focus on the use of scientific and technological innovations. This approach not only reduces labor and resource wastage but also greatly benefits the economic operation of transformers.

2 Choosing Appropriate Transformer Capacities

Considering the significant impact of transformer selection on the operation of power systems, enterprises should choose transformers with suitable designs. These transformers should be matched to the power station's supply load and voltage requirements. This helps address issues of excessive power consumption while reducing energy loss and conserving resources.

3 Conducting Necessary Testing Work

Before power transformers begin operation, relevant personnel should carry out scientific and rational testing work on the power system. Both AC and DC testing methods can be employed for this purpose. This approach not only ensures the safe testing of the power transformer's operational state but also prevents unnecessary complications, such as losses in power supply equipment. Consequently, it helps meet the economic operation requirements of power transformers.

35 kv 20000 kva power transformer Technical Parameter:

| Rated Capacity: | 20000 kva or 20 mva; |

| Mode: | S13-M-20000 or depends; |

| Voltage Ratio: | 35/11 kV, 35/10, 35/13.8 etc; |

| No loading loss: | 11.52 kW±15% or depends; |

| loading loss: | 79.515 kW±15% or depends; |

| Impedance: | 8.0% ± 15%; |

| Short Circuit Current: | ≤0.4%; |

| Temperature Rise: | 55K/65K, 60K/65K; |

| Cooling method: | Oil Nature Air Nature; |

CONSO·CN 35 Kv 20000 Kva Power Transformer Detail:

Transformer Winding:

Transformer in Application:

CONSO·CN 35 Kv 20000 Kva Power Transformer Workshop:

|

Winding Workshop |

Coil Drying Area |

Oil Filling Area |

Finished Product Area |

35 Kv 20000 Kva Power Transformer Testing Center:

35 Kv 20000 Kva Power Transformer Producing Equipment:

|

Transformer Oven |

Casting Equipment |

Foil winding machine |

CONSO·CN 35 Kv 20000 Kva Power Transformer Ready to Ship:

Package method:

|

Wooden Box |

Steel Structure |