- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

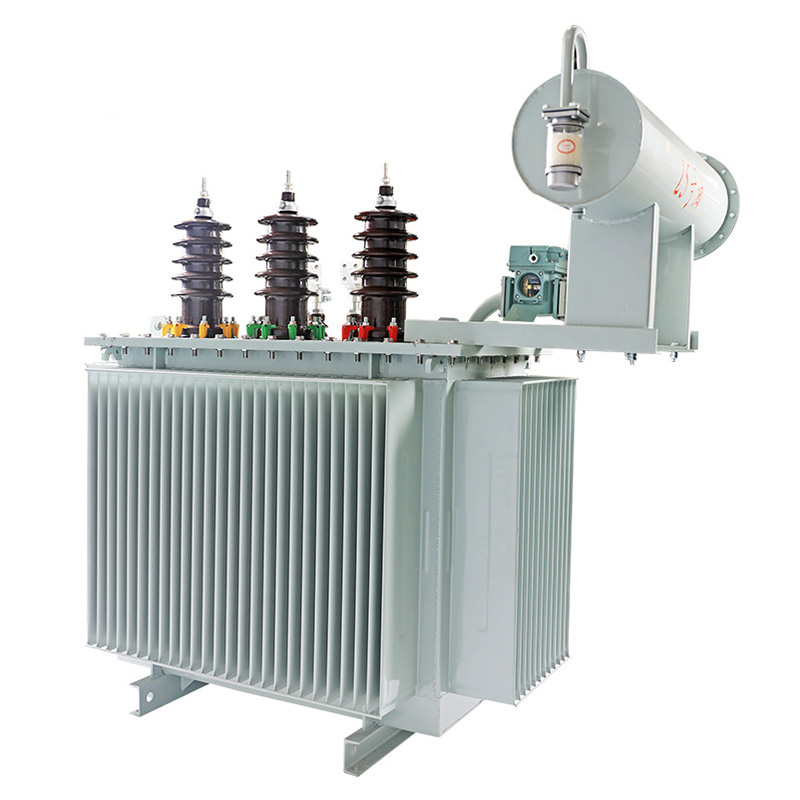

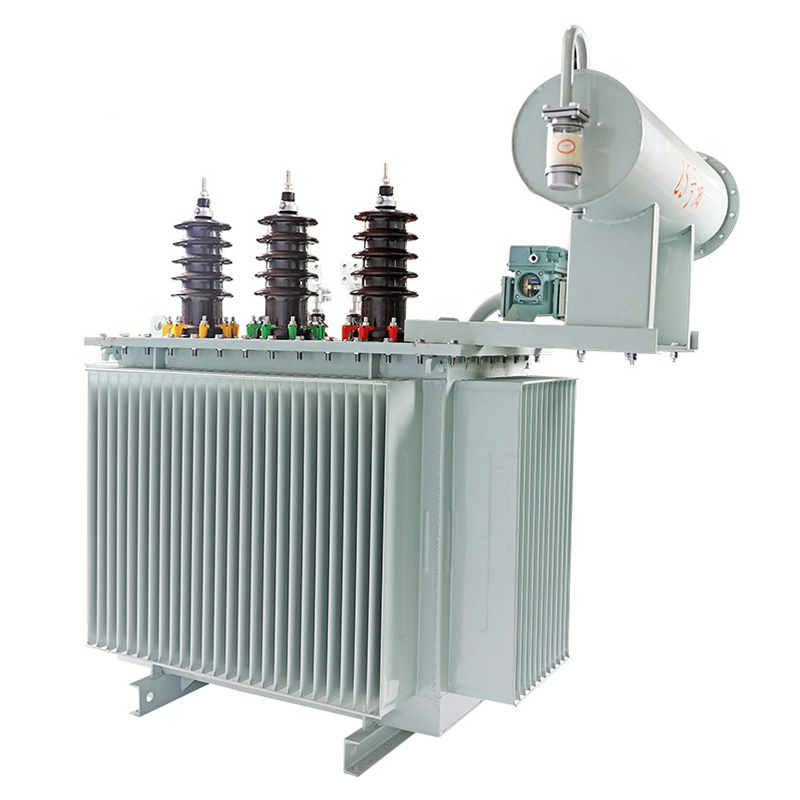

33kv 440v 1 Mva Solar Transformer

Send Inquiry

Video

33kv 440v 1 mva solar transformer Features:

1.For 10kV-level products, their moderate voltage level allows for convenient insulation structure handling. Typically, these transformers are designed with a traditional dual-winding dual-split structure. Two sets of low-voltage coils are axially split, and two sets of high-voltage coils are axially arranged. During casting, the two sets of coils are cast as one coil, and electrically, the two sets of coils are connected in parallel.

2.For 35kV-level products, the relatively higher voltage requires special structural treatment of the low-voltage coils to ensure good electrical performance, including features like partial discharge capacity and lightning impact resistance. After treating the low-voltage coils in the design process, the number of sections and layers of the high-voltage coils is reduced, maintaining a uniform electric field distribution within the coil.

3.In addition to these distinctions, the operational design steps for photovoltaic power transformers include: first, optimizing the photovoltaic power generation design, thoroughly understanding the site's basic characteristics, and refining the design proposal. Second, strengthening photovoltaic power generation infrastructure management, rigorously controlling qualification reviews, and standardizing the quality of photovoltaic power generation processes. Third, exercising strict control over photovoltaic power generation equipment to avoid the use of substandard equipment and products.

33kv 440v 1 mva solar transformer Technical Parameter:

| Rated Capacity: | 1000kVA or 1 mva; |

| Mode: | S11-M-1000 or depends; |

| Voltage Ratio: | 0.44/33 kV; |

| No loading loss: | adhere to IEC60076; |

| loading loss: | adhere to IEC60076; |

| Usage: | step up transformer; |

| Working temperature: | -40℃to 40℃; |

| Insulation type: | oil immersed; |

| Rated Frequency: | 50 or 60Hz; |

CONSO·CN 33kv 440v 1 mva solar transformer Detail:

Transformer Winding:

Transformer in Application:

CONSO·CN 33kv 440v 1 mva solar transformer Workshop:

|

Winding Workshop |

Coil Drying Area |

Oil Filling Area |

Finished Product Area |

33kv 440v 1 mva solar transformer Testing Center:

33kv 440v 1 mva solar transformer Producing Equipment:

|

Transformer Oven |

Casting Equipment |

Foil winding machine |

CONSO·CN 33kv 440v 1 mva solar transformer Ready to Ship:

Package method:

|

Wooden Box |

Steel Structure |