- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

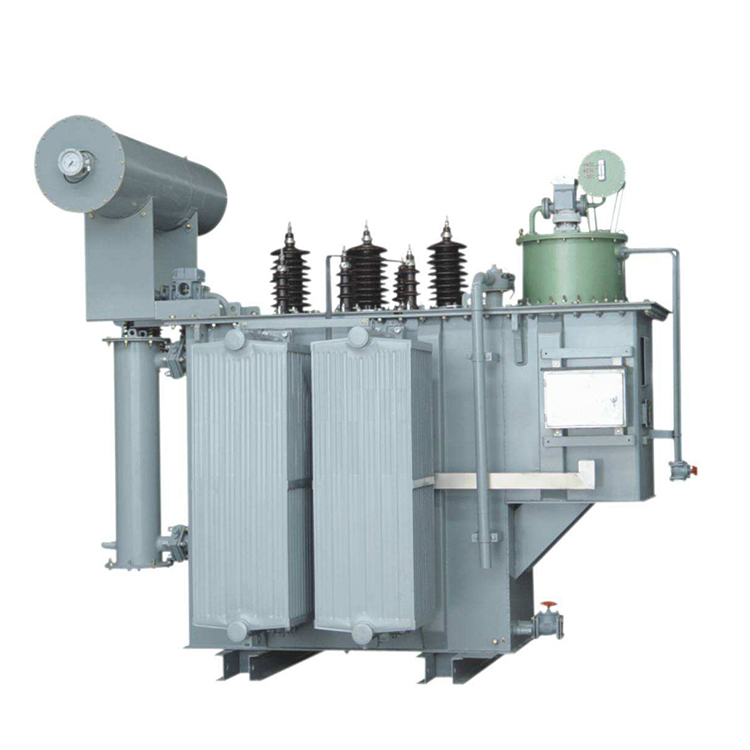

33kv 5000 Kva Power Line Transformer

Send Inquiry

Video

33kv 5000 kva power line transformer Maintenance:

1.Visual Inspection

Regularly inspect the exterior of the 33kv 5000 kva power line transformer for any damage or dirt. If there are noticeable cracks or corrosion on the 33kv 5000 kva power line transformer casing, it should be repaired or replaced promptly. Additionally, clean the transformer casing to prevent the accumulation of dust and debris.

2.Insulation Inspection

The insulation system of a 33kv 5000 kva power line transformer is crucial for its proper operation. Periodically inspect the insulation components of the 33kv 5000 kva power line transformer, such as insulation oil and insulating materials. During the inspection, check for signs of aging, damage, or leakage in the insulation components. If any issues are detected, they should be addressed promptly.

3.Oil Quality Check

Transformer oil is essential for the normal operation of a 33kv 5000 kva power line transformer. Regularly test the transformer oil to assess its insulation performance. Also, observe the oil for impurities, moisture, or any abnormal conditions. If issues are found, take appropriate actions promptly. Furthermore, regular oil replacement is necessary to ensure good insulation performance.

4.Temperature Monitoring

Monitor the temperature of the 33kv 5000 kva power line transformer during its normal operation. Periodic temperature checks can help identify any anomalies, such as overheating. If temperature irregularities are discovered, investigate the causes and implement necessary maintenance measures.

5.Cooling System Inspection

The cooling system of a 33kv 5000 kva power line transformer is critical for its proper operation. Regularly inspect the working condition of components in the cooling system, including the coolant, cooling fans, and cooling pipelines. Ensure that they are functioning correctly. If any faults or abnormalities are found in the cooling system, perform repairs or replacements as needed.

6.Safety Facility Check

33kv 5000 kva power line transformers are high-voltage equipment, and the integrity of safety facilities around them is crucial for ensuring personnel safety. Regularly inspect safety features around the 33kv 5000 kva power line transformer, such as protective enclosures and lightning protection devices, to ensure they are operational. If any issues with safety facilities are identified, address them promptly through repairs or replacements.

7.Maintenance Records

To better track the maintenance status of the 33kv 5000 kva power line transformer, it is advisable to keep records of each maintenance procedure. These records should include the maintenance date, personnel involved, and details of the maintenance performed. This helps in staying informed about the 33kv 5000 kva power line transformer's maintenance history and serves as a reference.

8.Preventative Maintenance

In addition to routine maintenance, preventive maintenance of the 33kv 5000 kva power line transformer should be emphasized. By implementing a regular maintenance schedule, you can inspect and address potential issues in advance, reducing the risk of breakdowns. Conduct routine operational monitoring of the 33kv 5000 kva power line transformer to identify and resolve latent problems promptly, improving its reliability and safety.

33kv 5000 kva power line transformer Technical Parameter:

| Rated Capacity: | 5 mva; |

| Mode: | SZ11-M-5000 or depends; |

| Primary Voltage: | 33kV; |

| Secondary Voltage: | 6.6kV, 10.5kV, 15kV, 20kV; |

| No loading loss: | 4640 W ±15% or depends; |

| loading loss: | 34200 W ±15% or depends; |

| Impedance: | 7.0 ±15%; |

| No loading Current: | ≤0.5%; |

| Vector Group: | Yd11; |

| Winding Material: | 100% Copper or 100% Aluminum. |

CONSO·CN 33kv 5000 kva power line transformer Detail:

Transformer Winding:

Transformer in Application:

CONSO·CN 33kv 5000 kva power line transformer Workshop:

|

Winding Workshop |

Coil Drying Area |

Oil Filling Area |

Finished Product Area |

33kv 5000 kva power line transformer Testing Center:

33kv 5000 kva power line transformer Producing Equipment:

|

Transformer Oven |

Casting Equipment |

Foil winding machine |

CONSO·CN 33kv 5000 kva power line transformer Ready to Ship:

Package method:

|

Wooden Box |

Steel Structure |